Old C-frames and O-frame scanners from 40 years ago are given a new life with modern electronics, X-ray sources, and X-ray detectors. At the same time, the C-frame or O-frame is refurbished but the overall dimensions remain the same, resulting in no changes of the mill mechanics. This substantially lowers the total project cost for the gauge replacement, and often cuts the required down-time in half.

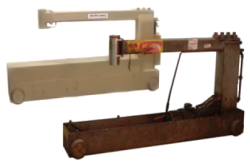

O-Frame Scanner Refurbishment and Re-Use: On a large coat weight gauge replacement project, re-using the existing O-frame structure can save nearly 30% of the overall project cost when mechanical modifications to the process line are no longer necessary and downtime is reduced. We have even been able to complete the O-frame conversion on a running line, resulting in no downtime at all! Our O-frame conversions often include new modern drive belts, motor, gearbox, AC drive, pulse encoder, and bearings, all commercial off-the-shelf parts with long life wear surfaces. Our engineers will study the past service history of the existing frame; remove those features and components that have been weak or difficult to service, and keep those features and components that have proven to be reliable and serviceable.

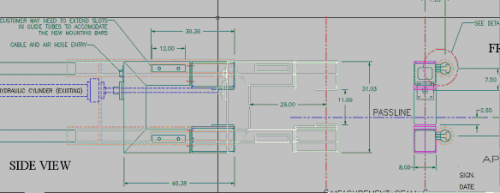

Our engineers can quickly model the intended upgrade and design a re-fit for the old gauge device that fits right in with existing mill structures and mechanical components.